Savira Aerospace

Private Limited

Pioneering aerospace & defense solutions with cutting-edge technology and quality excellence.

Engineering

& Technical Services

Comprehensive engineering solutions including design, analysis, prototyping, and technical consulting for aerospace and defense applications.

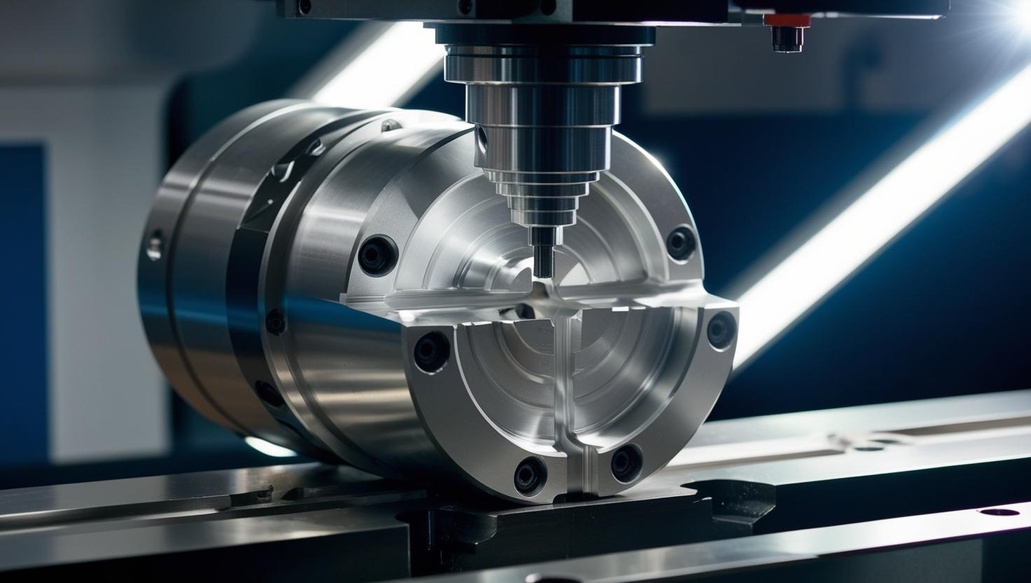

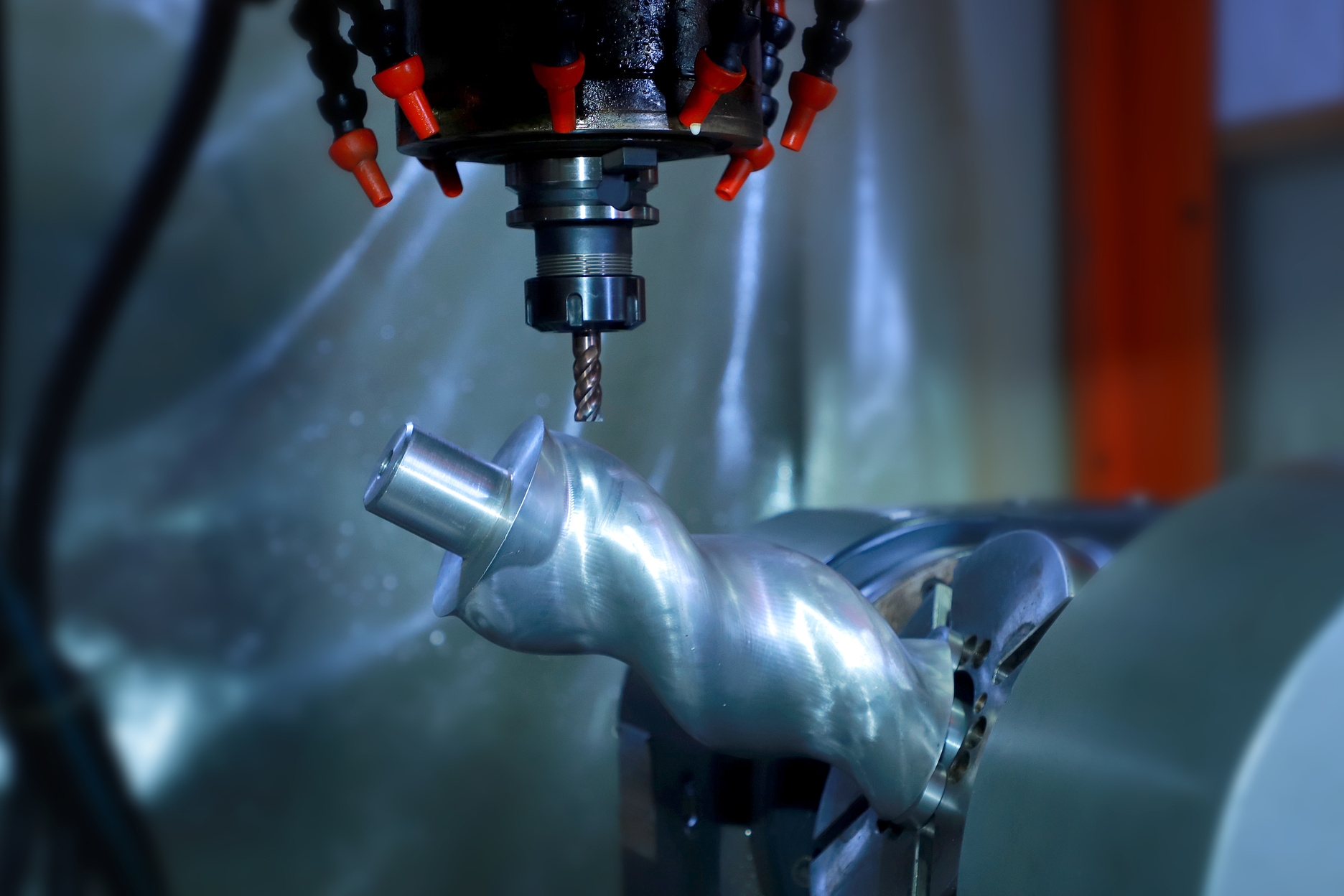

Manufacturing

Precision Machining & Assemblies

Advanced CNC machining, precision components, and integrated assembly solutions with stringent quality standards for critical applications.

Program Support

Design to Delivery

Coordinated engineering, supply chain, and project oversight that keeps aerospace builds on schedule.

Adibatla Facility

Taking Shape

A new plant with CNC machining, assembly bays, and integration cells is being commissioned to serve defense customers.

Integrated Design & Engineering

Concept development, detailed design, and subsystem engineering that align with manufacturability from day one.

Precision Manufacturing & Assemblies

CNC machining, value-added processes, and integrated assembly lines being established at the Adibatla plant.

Program & Supply Chain Support

Supplier development, material planning, and project coordination tailored for aerospace OEMs and defense programs.